Raccolta casi Working Model, visualNastran & SimWise - Sierra Pacific

Contatto Editoriale:

Paolo Lista,

Lista Studio srl®

Borgo Belvigo 33, 36016 Thiene Vi ITALY

tel/fax 0445,372479 o info@lista.it

VisualNastran Tests Designs for Stress, Buckling

Sierra Pacific Engineering and Products (SPEP), a leader in the industrial hardware industry, invests in technology to help design better products and retain its position in a competitive industry. This year, the company expects to improve design quality and reduce prototyping costs dramatically with visualNastran virtual prototyping software from MSC Software’s Working Knowledge division.

SPEP designs and manufactures hinges, locks, bolts, handles, latches, and pulls. Its products are made of steel, injection-molded plastic, aluminum, and die-cast zinc. The company sells its own product line directly to various manufacturers including precision sheet metal shops, electrical enclosure manufacturers, wood products manufacturers and the automotive industry to name a few. In the automotive industry, its products are found on utility trucks, recreational vehicles, and horse trailers. SPEP also designs and manufactures custom hardware.

Industrial Hardware: The Challenges

According to George Alvarado, SPEP’s engineering supervisor, the organization’s primary business challenges are reducing time to market and improving overall design to build higher quality products. While SPEP has been in the industrial hardware business for 13 years, it must deliver products to clients quickly if it wants to remain competitive.

"We pride ourselves on producing products on time, but we insist on producing quality product above all," Alvarado attests. "We don’t want to sell a hinge or latch that fails."

Virtual Prototyping On Board

In 1997, a client approached SPEP with a die-cast hinge to be redesigned for plastic for weathering characteristics and lower cost. The plastic had to be as strong as the die-cast hinge. The proposed part featured a rib configuration on the underside of the hinge to provide strength.

To meet the client’s requirement, SPEP evaluated three mechanical simulation software packages: Algor, ANSYS DesignSpace, and visualNastran from MSC Software.

"When we compared the other solutions to visualNastran we found a big difference," says Donald Rivadeneyra, a designer at SPEP. "I found the other programs difficult to use, and the results didn’t look very good graphically."

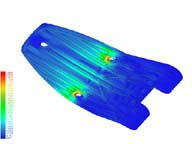

For the project, Rivadeneyra installed visualNastran, which he used for generating different configurations and narrowing design alternatives. "We created five different rib configurations for the underside of the part," Rivadeneyra explains. "By analyzing each part in visualNastran, we quickly determined which was the strongest."

According to Alvarado, in the past, the company machined each prototype or invested in a prototype mold. "If we created five different prototypes, five different rib configurations, it would have cost $5,000, required two weeks to machine, and up to two weeks to test. Now, we have a finished design in one to two days. Our costs are reduced dramatically."

FEA the Fix in a Multitude of Engineering Scenarios

Since then, SPEP designers and engineers have used visualNastran for a multitude of projects and varied engineering challenges. One design for the boat industry involved the creation of a custom flush-mount latch.

"The latch was designed to withstand 50 pounds of stress," Alvarado says. "But by optimizing the design with visualNastran software we created a latch that handles 70 to 80 pounds. It’s performing way beyond our expectations, expecially with the powerful design optimization."

VisualNastran also helped SPEP narrow down the best material for the injection-molded latch. Because the trailer would be used outside, the hardware had to weather everything from UV exposure to extreme temperatures, and heavy loads. With those potential wear problems in mind, Rivadeneyra contacted DuPont and obtained recommendations for three types of plastic.

"We simulated the product with the threematerials obtained from DuPont’s Web site, then through analysis in visualNastran selected the grade most likely to survive the temperature fluctuations and heavy loads," Rivadeneyra says. "The results look great, and we’re confident that the latch is strong."

Analysis Eliminates Guesswork

"Compared with we have now, we were blind," Alvarado says. "While we made very informed speculations to design a part, we were always aware that we spent too much time and money getting to our goal, which is to produce a superior product. Now when we invest in a prototype mold or a production mold, we are confident that the part will perform to our expectations."

"With virtual prototyping, I anticipate reducing prototyping costs by $15,000 or more this year," Alvarado continues. "That does not take into account the time we’ll save and time is money."

Typically, SPEP begins a design using Mechanical Desktop® from Autodesk, Inc. "Our customers are concerned with aesthetics, so we include them in the design process," Alvarado explains. "We e-mail a 3D model to our client, who downloads Spatial View, a viewer, to see SAT files generated in Mechanical Desktop."

SPEP clients can see and rotate the design in real time. If the customer approves the design, the engineering team completes the project with Mechanical Desktop and visualNastran, checking for interference problems, considering alternatives for saving materials, and improving the design. Then, SPEP submits final drawings and a stereolithography prototype, which is made in house to the customer for final design approval. If the client approves the final design, it goes to production.

"For me, having visualNastran integrated within Mechanical Desktop makes it easier to use," Rivadeneyra says. "I don’t have to close the program and import files."

SPEP designers and engineers use visualNastran for many scenarios, such as testing for stress or buckling. For one client, the company developed a plastic support shaft for a bed. SPEP applied 120 pounds of pressure to the support shaft, testing the bed for buckling and ensuring the bed was strong and safe in a few quick tests.

"Overall, visualNastran is reliable. It leads us in the right direction," Alvarado says. "It narrows down our design considerations considerably."

"One of the features I like is the Design Doctor," Rivadeneyra explains. "It walks me through the process and tells me where design flaws are located. I also like the software’s flexibility to run multiple scenarios. Overall, I appreciate the ability to present great-looking results to management or to a client."

"SPEP invests in new technologies that will help us design better hardware," Alvarado concludes. "We are always looking for tools to help us save money, deliver projects quickly, and better serve our customers, and visualNastran has been an invaluable part of our solution."

ALTRI 83 CASI IN SETTORI DIVERSI !