Raccolta casi Working Model, visualNastran & SimWise - NNC

Contatto Editoriale:

Paolo Lista,

Lista Studio srl®

Borgo Belvigo 33, 36016 Thiene Vi ITALY

tel/fax 0445,372479 o info@lista.it

NNC, Ltd. achieves efficiency and accuracy in nuclear reactor core analysis using advanced simulation software

When nuclear power plants operate at optimum efficiency they can be among the most effective sources of utility-level electrical power. A single plant can power an entire metropolitan region without significantly polluting the air or emitting greenhouse gases. But nuclear power presents risks too, and to ensure safe operation nuclear plant owners must constantly conduct rigorous reviews to demonstrate the safety and effectiveness of their operations.

As in any complex system, testing nuclear plant components can be detailed, time intensive and expensive. Depending on the plant function involved, test operations can reduce plant capacity or even shut down plant operations for extended periods sending operating costs skyrocketing. And, in some cases, these reviews require carrying out rig testing of

components or systems under representative in-reactor conditions.

As in any complex system, testing nuclear plant components can be detailed, time intensive and expensive. Depending on the plant function involved, test operations can reduce plant capacity or even shut down plant operations for extended periods sending operating costs skyrocketing. And, in some cases, these reviews require carrying out rig testing of

components or systems under representative in-reactor conditions.

NNC, Ltd., a nuclear energy pioneer and leader in plant construction and decommissioning throughout the United Kingdom and Europe, is making such testing more efficient and cost effective using Working Model Motion and Working Model 2D simulation software from MSC Working Knowledge.

"Working Model simulations are based strictly on the laws of physics, so our results are very reliable," explains Craig Mounfield. "We use the software to take the place of physical tests and to demonstrate engineering problems to clients and regulatory officials. Nuclear power now operates in a highly competitive electricity market in Great Britain, so safety, efficiency and cost-effectiveness are more important than ever. In every instance our savings to the company and client have been substantial."

Simulating Variables in the Core

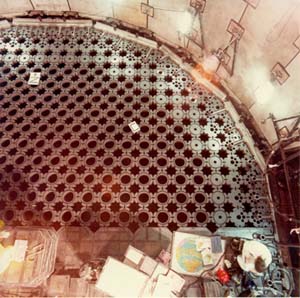

Impressively, NNC used MSC/Working Model software for simulating a wide range of reactor functions. Recently, the company successfully modeled and simulated the interaction of graphite bricks in a reactor's moderator core.

In the core, graphite bricks, which are stacked in columns typically 11 high and 20 in diameter, are used to slow down fast moving neutrons. Each column of bricks is intersected through the center with fuel which captures the slowed neutrons to produce a reaction, generating heat and more fast neutrons to repeat the process. The high operating temperatures combined with irradiation causes changes in the dimensions of the bricks, which can lead to changes in their relative positions

neutrons to repeat the process. The high operating temperatures combined with irradiation causes changes in the dimensions of the bricks, which can lead to changes in their relative positions

As Mounfield explains, "We used Working Model to construct a slice of a small region of the reactor core. The results of these simulations were then validated against results on an experimental test rig at our Research & Development Laboratory. We found that we were able to reproduce the experimental results to a very high degree of accuracy."

With simulation software, NNC was able to simulate a wide range of operating variables in the moderator core and graphically represent the results to the client. Furthermore, NNC will be able to run many additional virtual simulations at a fraction of the cost of the physical experiments.

"Simulation was a perfect answer for the moderator core analysis," says Mounfield. "We needed software that could explicitly and correctly model the physics of the interactions between rigid bodies over a wide range of operating conditions. Working Model handles rigid bodies exceptionally well and enables us to reduce the costs of test work substantially."

Effective Visualization, Easy Customization

Where virtual tests cannot entirely replace physical ones, NNC still uses simulations to illustrate concepts to customers, collaborating engineers and regulatory officials. "Simulation software helps us facilitate the relationships that we have with customers and their inspectors," explains Mounfield. "We can preview a test or problem long before we make any investment in the operation. We can also give clients and regulatory officials an opportunity to see the work that's underway and offer feedback or suggestions that we can verify in a test immediately. They enjoy the opportunity to be part of the process and much is less left to conjecture and speculation."

Because Working Model is affordable as well as easy to use and customize, NNC is able to train staff to use the software quickly and adapt it to specialized tasks. "Most people that work in the nuclear field are engineers and scientists," says Mounfield. "Working Model speaks that language and illustrates the results very effectively"

NNC leverages the software's flexible architecture to develop custom scripts that streamline complicated tests. The scripts are written in a variant of Visual Basic which, according to Mounfield, meshes exceptionally well with Working Model. "For experiments with an extensive number of variables, we'll set up scripts that enable users to enter data and conduct the simulation through dialog boxes or click commands. That flexibility makes Working Model a very powerful tool. The beauty of this approach is that the user does not need to have any knowledge of Working Model in order to utilize the functionality of the software."

This facility is currently being used to support a large, multi-disciplinary program of work including simulation, physical experiments and Finite Element Analysis. "Because we have the ability to run many different scenarios quickly, we can use Working Model as a tool to identify physical phenomena which are of significance to the core's behavior," explains Mounfield. "When such phenomena are identified they can be demonstrated and explained further with physical experiments that have been designed using Working Model."

In an industry where cost savings cannot compromise safety and standards, NNC have made simulation a critical part of their overall engineering solution, improving efficiency while reducing costs. With plants under increasingly intense scrutiny, simulation also helps Mounfield's team convey engineering concepts through an accessible and accurate graphical tool, speeding cost-critical decisions from clients and regulators. For Mounfield and NNC, simulation software has proven to be the right tool for the times. "As a physicist, I'm always amazed by the phenomenal engineering that goes into building a reactor. They remain a considerable engineering challenge, so having a tool like Working Model to assist us in maintaining something this complex is a major advantage."

ALTRI 83 CASI IN SETTORI DIVERSI !